The foods you feed to your fish can affect their health, energy levels, and even their coloration. If your fish are lethargic or not looking their best, you should consider the quality and variety of the food they're receiving. Here I'll share some basics on fish food followed by my favorite fish foods that I always keep on hand in my fish room. I'll start with the most common staple: fish flakes. After that we'll move into other dry foods, then frozen foods, and finally live foods.

Note: This article contains affiliate links to buy many of my favorite fish foods on Amazon, but I recommend you first shop for them at your local fish store.

Fish Food Basics

Prepared fish foods come in many types; flake, pellets, granules, wafers, etc. The form you choose is mostly determined by the size and feeding behavior of the fish you're feeding. Surface feeders do well on flakes, while bottom feeders prefer sinking pellets or algae wafers. Some foods are mostly fish meal (yes, fish eat other fish) and some are mostly algae-based. Its good practice to offer a variety of foods rather than just one to ensure all of your fish are getting a varied diet.

Another thing to keep in mind is that fish foods have a shelf life. Even if the expiration date printed on the container hasn't passed, the food begins to lose its nutritional value over time once exposed to air. If you've been using the same large container of fish flakes for over a year, its likely that the vitamins and nutrients in that food have mostly degraded. At that point, your fish aren't receiving adequate nutrition and therefore likely won't look their best. Although its cheaper to buy in bulk, to keep fish food fresh you should only buy 3-6 months worth at a time.

My Favorite Fish Flakes

When it comes to flake foods, there are two staples that I recommend. The first is Xtreme Aquatic Foods Krill Flake, and the other is spirulina flakes. Krill are small crustaceans that many fish eat in their native habitats. Krill flakes are highly nutritious and can improve coloration in your fish because they contain carotenoids that fish use to produce pigments. Spirulina is a biomass of cyanobacteria, also known as blue-green algae. These green flakes are more than 50% protein and contain fatty acids and B vitamins. Some local fish stores will sell krill and spirulina flakes by the ounce, as both are used in commercial fish farming.

My Favorite Fish Pellets and Wafers

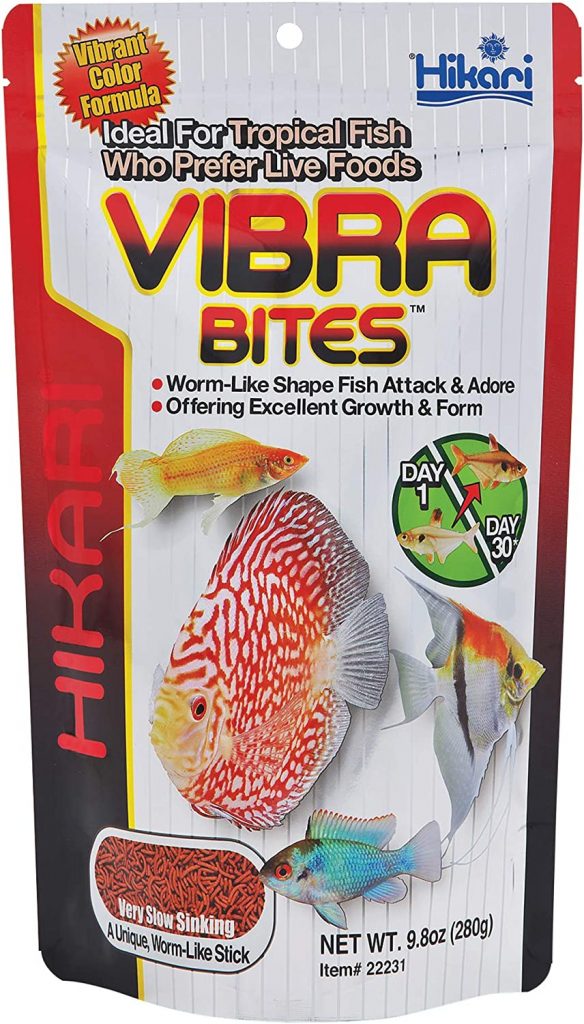

When it comes to wafers, granules, and pellets I use Hikari foods in my fish room. Hikari's line offers a variety of high quality prepared food sizes and ingredients. My rainbowfish eat Vibra Bites as a regular stable. In my experience, fish go nuts for Vibra Bites from the first time they see it. These "worm-like sticks" look very similar to blood worms, which I believe causes fish to go after them aggressively.

I also like Hikari's micro pellets and micro wafers for smaller fish like guppies. I keep several different Hikari dry foods on hand in my fish room so that I can rotate between them and offer my fish a varied diet.

My Favorite Frozen Fish Foods

In addition to the dry foods I've listed, I always keep a couple packs of frozen fish food in my freezer. My preferred frozen foods are blood worms and brine shrimp. There is a huge variety of frozen foods out there, and you should try a few to see what your fish like. When it comes to frozen foods, I recommend buying at your local fish store. The cost to ship a box of ice will rarely be worth it, and every fish store I have ever been in has had a freezer full of various frozen foods.

Support your local fish stores!

My Favorite Live Fish Foods

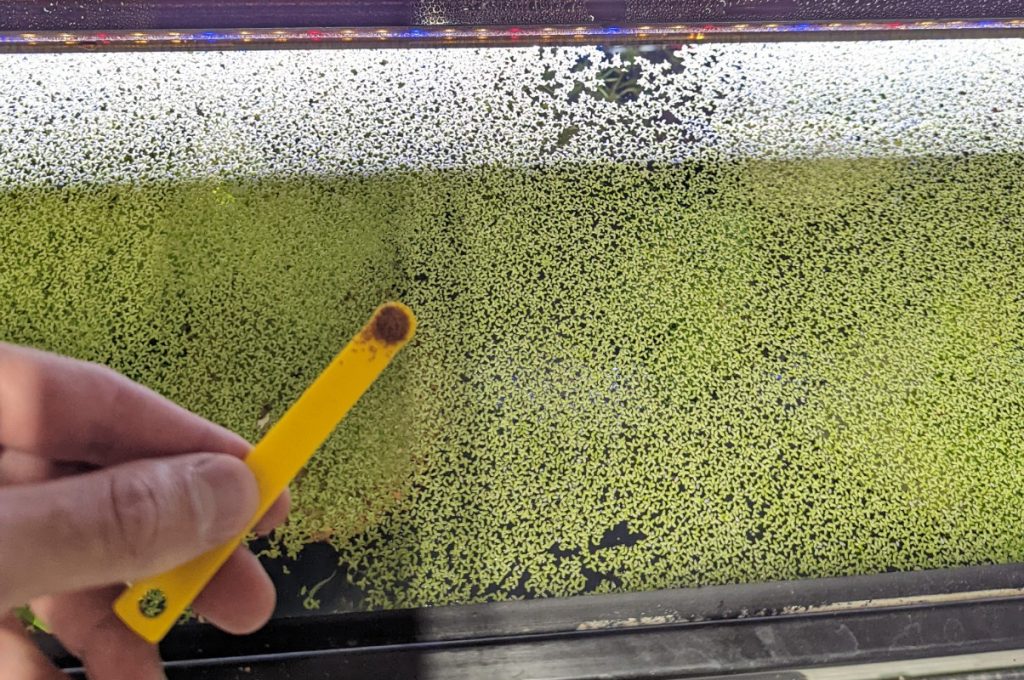

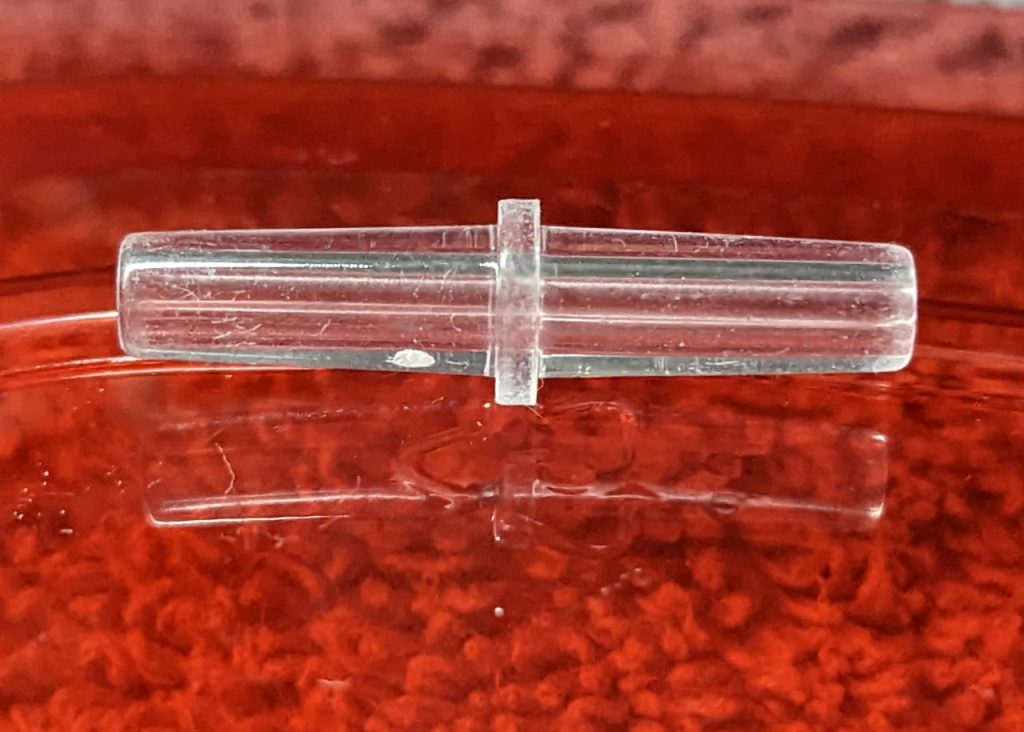

If you've made it this far you're ready to prepare the highest quality sustenance you can offer your fish: live foods! No prepared or processed food can offer the nutritional value that live prey offers. In a stream, river, lake or ocean, fish will feed on a variety of tiny worms, crustaceans and copepods. Two of the easiest live foods to prepare and feed to your fish are baby brine shrimp and microworms. These two foods are good for smaller fish, particularly when raising fry. You can read my post on hatching baby brine shrimp here. And you can read this post for more info on microworms.

There are a variety of other live foods you could offer your fish: vinegar eels, peanut beetle larvae, daphnia, black worms, and many more. The live foods you choose will depend on the size and dietary needs of the fish you're keeping. Hopefully this post will serve as a jumping off point for you to go and do some research on the many live fish food options out there to find what works for you.

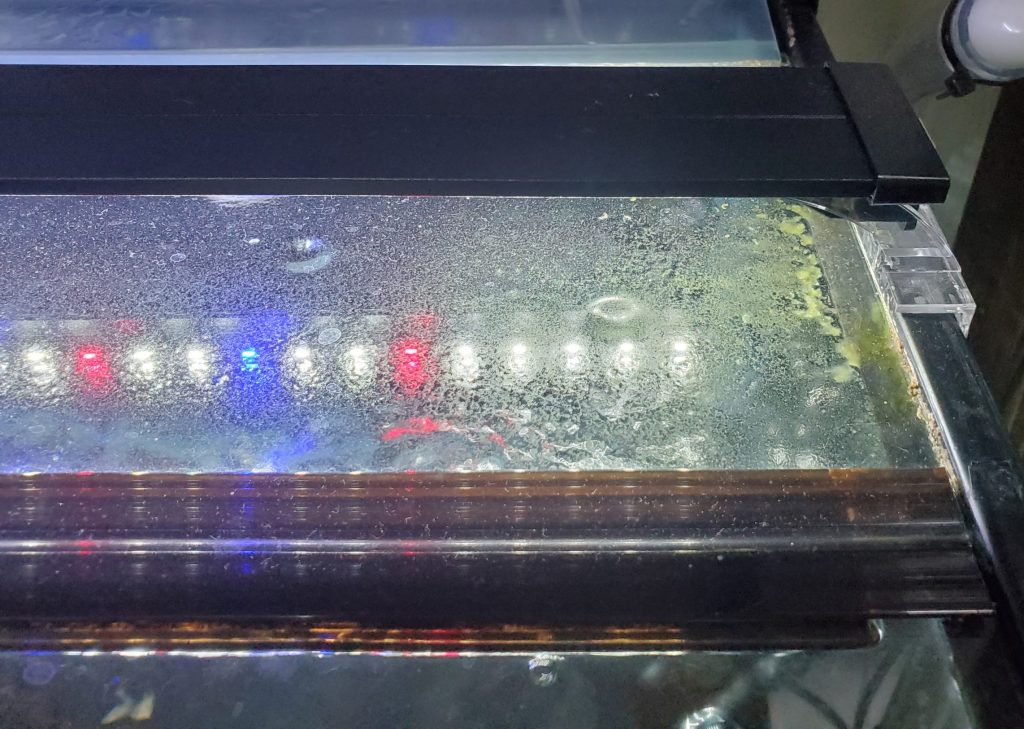

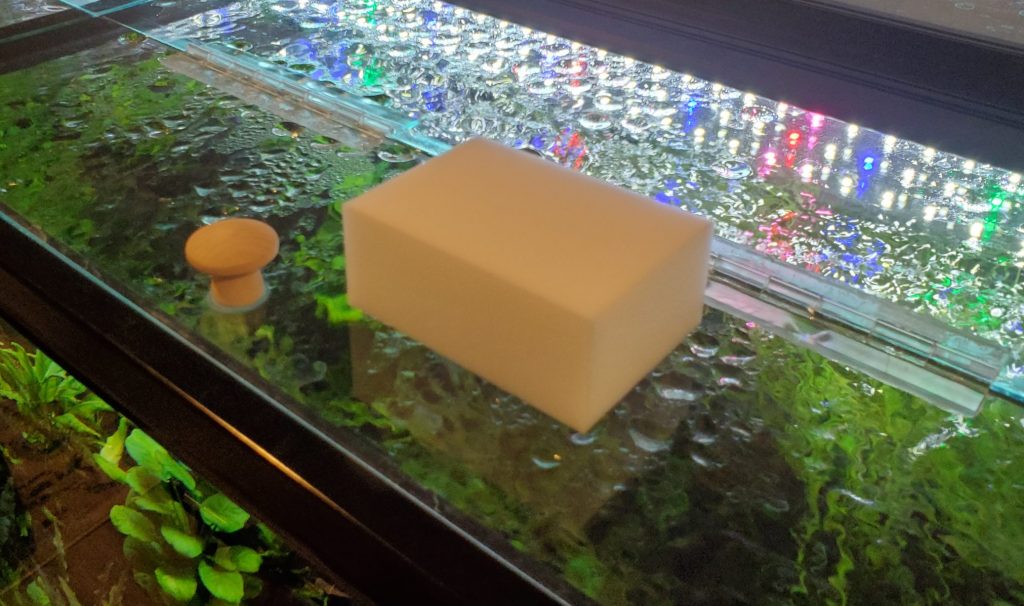

Too many floating plants in your tank? Check out this post on making your own floating feeder ring